Improved process capability means centring a process parameter on a specified target, and reducing the process spread within specification limits. A process capability analysis is only meaningful if the defined specification limits accurately reflect the needs of the final product.

Smaller is Cpk, bigger are deffects. A low Cpk means one of three things: the mean is far from the center of the limits, or standard deviation of the readings is too high (wide spread), or both conditions exist.

Common rules defines a threshold of 1.33 for Cpk. In the industry, a Cpk of less than 1.66 needs a closer look. A Cpk that’s less than 1.33 needs some action to make it higher, and a Cpk of less than 1.0 means that the process is not capable of meeting its requirements.

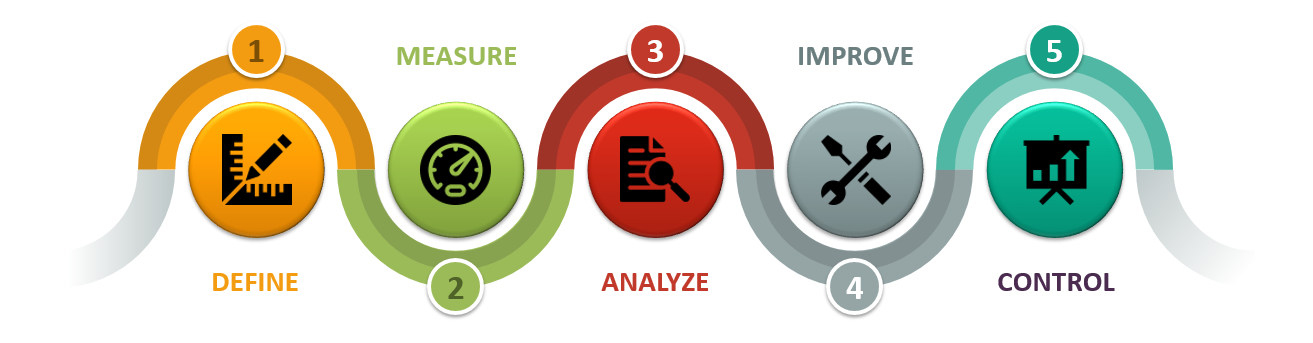

Define, measure, analyze, improve, and control (DMAIC) strategy is a scientific approach for reducing the deviations and improving the capability levels of the manufacturing processes. CPK Analyzer module has been designed to simplify data collection and processing as well as data analysis.

DMAIC can be implemented as a standalone quality improvement procedure or as part of six sigma method.

1. Define

Define the problem, goal, potential resources, project scope and timeline.

2. Measure

Measure and collect data according to defined strategy and ensure data is reliable and significant.

The performance metric baseline(s) from the Measure phase will be compared to the performance metric at the conclusion of the project to determine objectively whether significant improvement has been made.

Key tools in this phase may include process capability measurement, basic Pareto charts, trend charts, process flowcharts and Gage R&R.

CPK Analyzer module has been designed to simplify the processing of collected data as well as their analysis.

3. Analyze

Analyze the data collected and process map to determine:

- Root causes of variation and poor performance (defects)

- Opportunities for improvement.

4. Improve

Improve the target process by selecting solutions to fix and prevent problems.

Implement the solutions.

Measure to ensure improvement.

Easily compare results using CPK Analyzer compare feature.

5. Control

Control the process improvements post implementation to ensure expected improvement in project has occurred.