Measurement system is the collection of instruments or gages, standards, operations, methods, fixtures, software, personnel, environment and assumptions used to quantify a unit of measure or fix assessment to the feature characteristic being measured; the complete process used to obtainthe measurement.

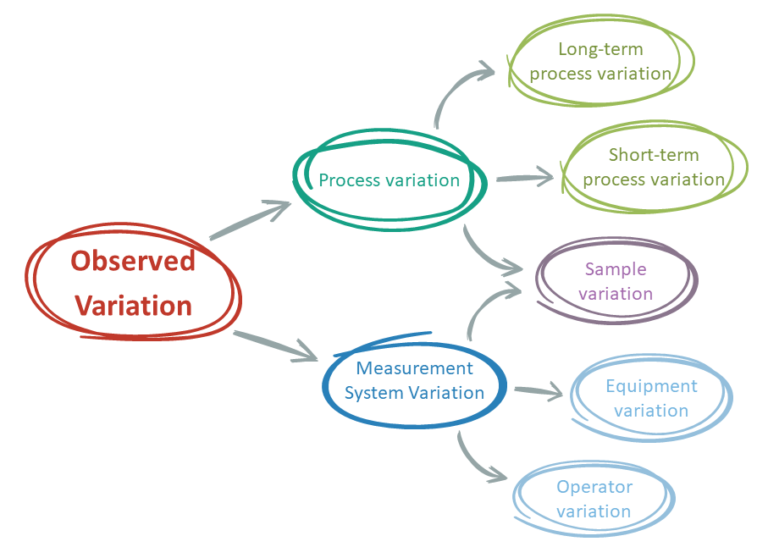

Whenever you measure anything, the observe variation can be segmented into the following sources:

The sources of variation in a measurement process can include:

- Process – test method, specification

- Personnel – the operators, their skill level, training, etc.

- Tools / Equipment – gages, fixtures, test equipment used and their associated calibration systems

- Items to be measured – the part or material samples measured, the sampling plan, etc.

- Environmental factors – temperature, humidity, etc.

All of these possible sources of variation should be considered during Measurement System Analysis. Evaluation of a measurement system should include the use of specific quality tools to identify the most likely source of variation. Most MSA activities examine two primary sources of variation, the parts and the measurement of those parts. The sum of these two values represents the total variation in a measurement system.